With the development speed of science and technology, more and more display products are now equipped with touch screens. Resistive and capacitive touch screens are already ubiquitous in our lives, so how should terminal manufacturers customize the structure and LOGO when supporting touch? What details should be paid attention to when customizing?

Here we start from 6 details to introduce the resistance and capacitance touch screen customization scheme in detail:

1. Touch parameters

First, you need to confirm that the product is suitable for capacitive or resistive touch screens, and confirm the operating temperature, storage temperature, interface and other parameter requirements. It is best to focus on discussing and sorting out the parameter requirements table, which can greatly shorten the early communication time.

2. AA size and outer frame size

After confirming the required parameters, next confirm the product size. The size is mainly the AA area of the touch screen and the size of the outer frame. These two sizes are generally designed based on the structure. The structural engineer draws CAD drawings for confirmation, which can improve customization efficiency.

3. Touch cover logo

For full-flat capacitive touch screens, the touch screen cover can be customized. Silk-printed LOGO or pictures can be customized on the touch screen. If customers need to customize the cover, they can also communicate with the manufacturer in time.

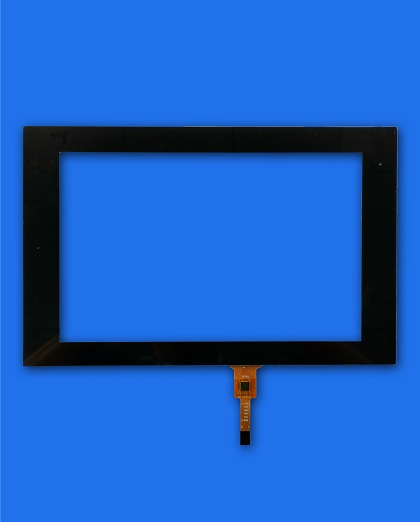

4. Touch screen structure

There are many types of touch screens, including G+G, G+F+F, G+F, G+P, etc. Please confirm the touch structure. Each structure has its own characteristics. You can contact customer service to provide various The advantages and disadvantages of this structure.

5. Touch screen fit

There are generally two types of touch lamination methods: optical bonding and air bonding. Optical bonding uses a fully automated machine for water glue lamination. Its advantages are better display effect and dust resistance, while air bonding is stronger. Each has its own advantages, and different industries use different lamination methods.

6. Touch screen IC debugging

Touch screen samples will be debugged after leaving the factory. The programming procedures will be different for different ICs. Some mainboards have poor compatibility, so debugging and changing the program are required to achieve smooth touch functions.

Finally, let’s summarize the issue of touch screen customization delivery time. The delivery time is more important to the purchaser. Generally, if you only customize the touch cover glass, the delivery time is usually between 1 week and 2 weeks. If the touch screen is customized as a whole, the delivery time is about 20 days, depending on the condition of the original materials. If the materials are incomplete, the delivery date will be confirmed separately.

DISEN ELECTRONICS CO., LTD specializes in customizing LCD screens, TP, and can customize products according to user requirements. If you have any questions, please feel free to consult customer service online.

Post time: Feb-29-2024