1.Automatic Optical Inspection, it refers to a detection method that obtains the image of the object under test by optical imaging, processes and analyzes it with a specific processing algorithm, and compares it with the standard template image to obtain the defect of the object under test. AOI equipment detection precision is high, fast, but also the production process of the work quality and the type of defects and other situations collected, feedback back, for process control personnel analysis and management. It is the most widely used detection method at present.

1.Automatic Optical Inspection, it refers to a detection method that obtains the image of the object under test by optical imaging, processes and analyzes it with a specific processing algorithm, and compares it with the standard template image to obtain the defect of the object under test. AOI equipment detection precision is high, fast, but also the production process of the work quality and the type of defects and other situations collected, feedback back, for process control personnel analysis and management. It is the most widely used detection method at present.

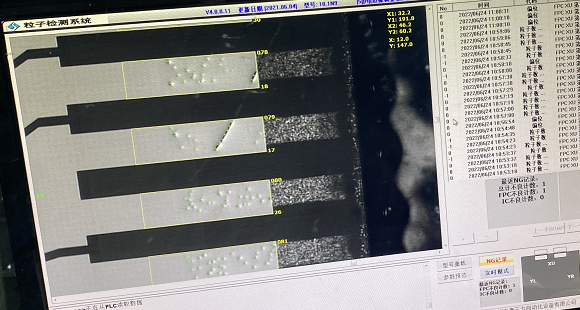

2.Automatically check the number of conductive particles at the bonding position and the bonding effect through a high-precision machine, and determine good and bad products.

Simplify the product process, While reducing the cost of human inspection, it also greatly reduces the economic cost caused by the outflow of defective products caused by manual inspection.

3.The introduction of online AOI realizes a one-step fully automatic production process from raw materials to inspection

Post time: Sep-22-2022